At Aircond.Network, we specialize in delivering high-quality HVAC maintenance and repair services to ensure your systems operate at peak performance year-round. With over 25 years of industry experience, our team is committed to optimizing your equipment’s efficiency, reliability, and lifespan.

We provide comprehensive maintenance services for essential HVAC equipment, ensuring your systems run smoothly, efficiently, and cost-effectively. Routine servicing is critical to extending the lifespan of your equipment, preventing unexpected breakdowns, and optimizing energy efficiency. By adhering to a regular maintenance schedule, you can avoid costly repairs, reduce downtime, and maintain consistent comfort levels. Explore the detailed scope of work for each equipment type below to see how our services can keep your systems in peak condition year-round.

Routine servicing, including vibration analysis and lubrication of moving components, minimizes the risk of breakdowns.

All mechanical and electrical parts, such as compressors, fans, and controls, are inspected for wear and tear.

A chiller Annual Shut Down (ASD) is recommended which consist of condenser and evaporator tubes cleaning to enhance heat exchange and prevent scaling; replacement of oil filter, filter drier, compressor oil; and conduct oil sampling test by accredited laboratories to assess operating condition of chiller.

Refrigerant levels are checked and adjusted to maintain optimal system performance.

We evaluate your chiller’s operational needs and assess your facility’s cooling requirements.

Fill media, drift eliminators, and other internal components are cleaned to prevent scaling, corrosion, and microbial growth.

Fans, motors, belts, and pulleys are inspected and adjusted for peak performance.

The cooling tower’s framework is inspected for signs of wear and corrosion, ensuring safety and durability.

Operational tests are conducted to evaluate efficiency and identify areas for improvement.

We monitor and treat water to maintain optimal conditions and minimize scaling and corrosion. We comply with Singapore NEA regulations by providing chemical/ non chemical water treatment for your cooling towers.

Inspect Internal and external parts includes cleaning drainline, fins, coils and greasing.

Thorough checking of motor, fans, blades, belts are checked and adjusted to ensure efficient and silent running condition.

Cleaning or replacement to achieve optimum indoor air quality and maintain efficient airflow.

Tested and calibrated to ensure accurate airflow requirements.

We begin by understanding your specific cooling needs and assessing your property’s layout, size, and usage patterns.

Our experts design a customized FCU solution tailored to your property’s unique requirements, ensuring efficient cooling and airflow.

Our certified technicians handle the installation process with precision, ensuring every component is installed correctly and safely.

After installation, we thoroughly test the FCU to ensure it operates at peak performance and meets all safety standards.

We begin by understanding your specific cooling needs and assessing your property’s layout, size, and usage patterns.

Our experts design a customized FCU solution tailored to your property’s unique requirements, ensuring efficient cooling and airflow.

Our certified technicians handle the installation process with precision, ensuring every component is installed correctly and safely.

After installation, we thoroughly test the FCU to ensure it operates at peak performance and meets all safety standards.

We begin by understanding your specific cooling needs and assessing your property’s layout, size, and usage patterns.

Our experts design a customized FCU solution tailored to your property’s unique requirements, ensuring efficient cooling and airflow.

Our certified technicians handle the installation process with precision, ensuring every component is installed correctly and safely.

After installation, we thoroughly test the FCU to ensure it operates at peak performance and meets all safety standards.

We begin by understanding your specific cooling needs and assessing your property’s layout, size, and usage patterns.

Our experts design a customized FCU solution tailored to your property’s unique requirements, ensuring efficient cooling and airflow.

Our certified technicians handle the installation process with precision, ensuring every component is installed correctly and safely.

After installation, we thoroughly test the FCU to ensure it operates at peak performance and meets all safety standards.

We assess the motor’s role within your HVAC system to tailor maintenance tasks.

Motor windings, insulation, and electrical components are thoroughly inspected and tested.

Bearings are cleaned and lubricated to reduce friction and prevent premature failure.

Motors are aligned and balanced to ensure smooth operation and energy efficiency.

Voltage, amperage, and load testing are conducted to monitor motor efficiency.

We assess the motor’s role within your HVAC system to tailor maintenance tasks.

Motor windings, insulation, and electrical components are thoroughly inspected and tested.

Bearings are cleaned and lubricated to reduce friction and prevent premature failure.

Motors are aligned and balanced to ensure smooth operation and energy efficiency.

Voltage, amperage, and load testing are conducted to monitor motor efficiency.

Our specialized repair solutions are designed to restore the functionality and efficiency of your HVAC systems. See how we address repairs for various equipment types.

We thoroughly assess the cooling tower to identify the root cause of operational issues, including irregular airflow, leaks, or structural damages as the cooling towers are on the outdoor adverse weather conditions.

Damaged fans and motors are repaired or replaced to restore functionality and efficiency.

Framework, basins, and casing are inspected and repaired to ensure structural integrity.

Replacement of clogged, worned or damaged infill media improves the heat exchange and cooling performance for the chiller’s performance.

Fill media, drift eliminators, and other internal components are cleaned to prevent scaling, corrosion, and microbial growth.

Fans, motors, belts, and pulleys are inspected and adjusted for peak performance.

The cooling tower’s framework is inspected for signs of wear and corrosion, ensuring safety and durability.

Performance Monitoring: Operational tests are conducted to evaluate efficiency and identify areas for improvement.

We monitor and treat water to maintain optimal conditions and minimize scaling and corrosion. We comply with Singapore NEA regulations by providing chemical/ non chemical water treatment for your cooling towers.

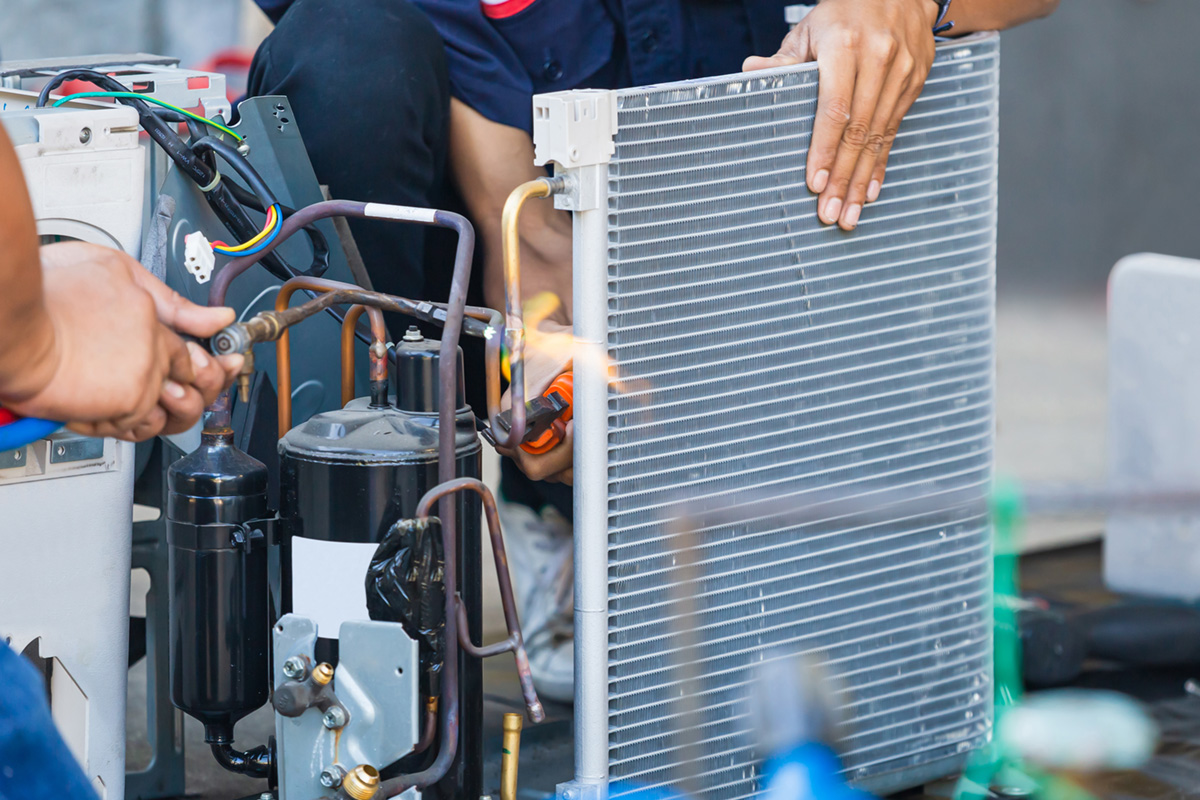

We repair or replace faulty compressors to restore the cooling capacity of your direct expansion unit.

Leaks are repaired, and refrigerant levels are optimized for efficient operation.

Our team conducts comprehensive pressure tests to ensure system integrity and prevent future leaks.

Faulty wiring and electrical components are replaced to ensure safe and reliable operation.

We address issues with fans and coils to improve airflow and heat transfer efficiency.

We begin by understanding your specific cooling needs and assessing your property’s layout, size, and usage patterns.

Our experts design a customized FCU solution tailored to your property’s unique requirements, ensuring efficient cooling and airflow.

Our certified technicians handle the installation process with precision, ensuring every component is installed correctly and safely.

After installation, we thoroughly test the FCU to ensure it operates at peak performance and meets all safety standards.

We repair duct insulation to prevent condensation and energy loss.

We restore or replace insulation to maintain optimal temperature control.

Damaged ducts are repaired or replaced to restore structural integrity and performance.

We begin by understanding your specific cooling needs and assessing your property’s layout, size, and usage patterns.

Our experts design a customized FCU solution tailored to your property’s unique requirements, ensuring efficient cooling and airflow.

Our certified technicians handle the installation process with precision, ensuring every component is installed correctly and safely.

After installation, we thoroughly test the FCU to ensure it operates at peak performance and meets all safety standards.

We replace damaged bearings to ensure smooth motor operation and reduce friction.

Damaged windings are repaired or rewound to restore motor functionality.

Motors are aligned and balanced to reduce vibrations and improve efficiency.

Faulty wiring and electrical components are repaired or replaced to ensure safe operation.

Use thermal imaging to check for hotspots on the motor, which could indicate overheating or issues such as electrical faults or mechanical stress.

We assess the motor’s role within your HVAC system to tailor maintenance tasks.

Motor windings, insulation, and electrical components are thoroughly inspected and tested.

Bearings are cleaned and lubricated to reduce friction and prevent premature failure.

Motors are aligned and balanced to ensure smooth operation and energy efficiency.

Voltage, amperage, and load testing are conducted to monitor motor efficiency.

Get a Quote Today!